High Visibility Safety Vests Explained with ANSI Classes Colors, and Real Work Examples

By: YouApparel Posted on: Nov 13, 2025Why High-Visibility Vest Matters

Their Premium Brilliant Series 1510-1511 Heavy Duty Class 2 Vest exemplifies professional construction with ANSI Class 2 compliance, polyester mesh, 2-inch reflective striping, and six pockets. Reinforced webbing and precision reflective placement explain why municipalities and contractors trust Kishigo.

Decoding Safety Vest Colors

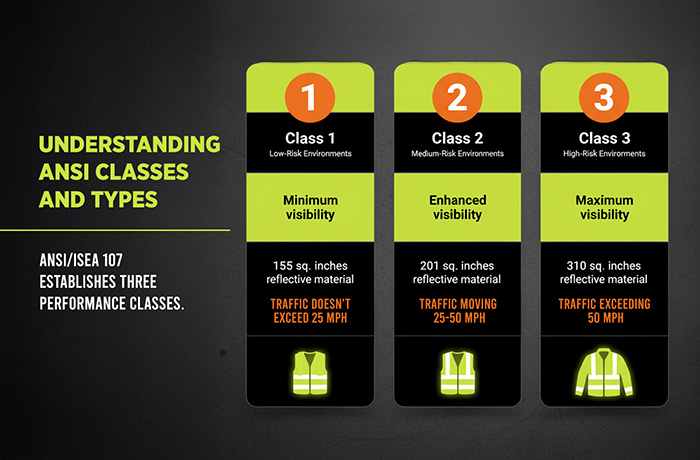

Understanding ANSI Classes and Types

- Class 1 provides minimum visibility for low-risk environments. Parking attendants and warehouse workers wear Class 1 vests with 155 square inches of reflective material where traffic doesn't exceed 25 mph.

- Class 2 is required when workers face traffic moving 25-50 mph. These include 201 square inches of reflective tape for 360-degree visibility. Road crews and utility workers depend on Class 2 protection.

- Class 3 offers maximum visibility for workers exposed to traffic exceeding 50 mph, featuring sleeves with 310 square inches of reflective material. Highway crews and flaggers need Class 3 garments.

Materials That Make the Difference

About Closure Mechanisms

Importance of Reflective Details in Safety Vests

Additional Useful Features of Safety Hi-Vis Vests: Pockets & Storage

- Chest pockets with mic tabs for radios

- Two-tier pencil pockets for instruments

- Lower cargo pockets for gloves and tools

- Inside patch pockets for phones

- Clear ID windows for credentials

- Back document pockets for maps

Industry Applications of Safety Vests: Breakdown

- Construction and Road Work require Class 2 or 3 vests. Orange safety vests are commonly preferred.

- Flaggers can use Class 3 lightweight vests for both freedom of movement and visibility.

- Warehouses use Class 1 vests for forklift operators, where colored vests distinguish departments.

- Surveying professionals need vests with pockets. The Kishigo 1510 combines Class 2 visibility with six pockets.

- Public Safety uses Type P vests.

- Recreational cyclists and runners can wear lightweight reflective vests for personal safety.

Cost and Value Considerations

Key Innovations and Technology

- LED-Integrated Vests add battery-powered strips. USB-rechargeable batteries can last 8-12 hours.

- Cooling Technologies uses phase-change materials. Advanced insulated vests may incorporate hydration packs.

- Smart Wearables monitor vital signs, location, and conditions. Temperature sensors alert supervisors to heat risks.

- Sustainable Materials: Some Kishigo safety vests in our wholesale collection use recycled materials, reducing carbon emissions significantly.

- Reflective Yarn woven into fabric maintains visibility after 50+ washes.

Making Smart Decisions

- Match the ANSI class to work risks.

- Choose materials for your climate.

- Calculate total ownership cost.

- Select pockets that eliminate extra belts.

- Prioritize established brands like Kishigo.

Frequently Asked Questions

How do I know if a vest meets ANSI/ISEA 107 standards?

Look for several indicators when verifying ANSI compliance like labels or tags stating “ANSI/ISEA 107” and type designation (O, R, or P). You can also assess the quality of reflective tape - whether it’s bright enough and uniform. It’s also a good idea to buy safety vests from established brands like Kishigo, CornerStone, etc. as these manufacturers consistently deliver ANSI-compliant garments. Non-ANSI vests are simply brightly colored garments without reflective tape and should not be used in OSHA-regulated environments.

What does Type O, Type R, and Type P mean in safety vest classifications?

Type designations indicate the intended work application, separate from Class ratings. Type O for Off-Road are garments designed for controlled environments where traffic speed is limited. They are typically in Class 1 configuration. Type R for Roadway are garments for workers exposed to traffic on public roads and highways. This is the most common type for road crews, utility workers, and emergency responders. Type R vests are available in Class 2 and Class 3 configurations. Type P for Public Safety is specifically designed for law enforcement, emergency medical services, and fire departments. These vests feature specialized reflective patterns and may include additional pockets for equipment, radio holders, or ID panels. Type P vests often come in Class 2 or higher. Municipalities purchasing for police and emergency services typically require Type P designation.

Are flame‑resistant vests different from fire‑retardant vests?

Yes. They are made of two fundamentally different materials with different protection levels. Flame-resistant vests or “flame vests” as they are sometimes referred to, are made from inherently flame-resistant fibers like Modacrylic, Nomex®, or Indura®. The fiber itself doesn't burn, melt, or drip when exposed to flame. FR vests self-extinguish when the flame source is removed. Modacrylic is the most common and affordable FR option. Fire-retardant vests use standard polyester treated with chemical fire-retardant coatings. The base fiber is polyester, which will melt if exposed to intense heat. However, the chemical treatment causes the fabric to self-extinguish when flame is removed. The protective coating degrades with each washing, requiring manufacturer-specified washing protocols to maintain efficacy.

Should I choose a mesh vest or a solid‑fabric vest for my job?

This decision depends on your work environment, climate, durability needs, and customization plans. Mesh vests are ideal if the weather is hot and you want breathability. But it typically isn’t durable, unless you invest more on offerings from reputed brands. Solid Polyester or combination vests are really durable, and typically withstands entanglement. Solid front and mesh back is more balanced but heavier. It offers more heat retention but costs slightly more comparatively.

Is a non‑ANSI vest acceptable for warehouse work?

It depends. For internal warehouse use where forklifts don't operate, non-ANSI colored vests work fine for identification. However, OSHA recommends Class 1 vests for forklift areas and anywhere workers face equipment or traffic. Non-ANSI vests are bright colors without reflective tape. So they won't protect workers near moving machinery.

Which color is best for high‑visibility vests in low‑light conditions: yellow or orange?

Yellow performs slightly better in total darkness due to superior fluorescence. However, both yellow and orange meet ANSI standards. For nighttime work, choose vests with retroreflective tapes over color.

Can I use blue or green vests on a construction site?

Not for OSHA-regulated work. Blue and green are non-ANSI colors used for identification only (security, first aid, park rangers). Construction sites require ANSI Class 1, 2, or 3 vests in yellow, orange, or red. Using blue or green instead risks regulatory violations and worker safety.

Can I wear a safety vest over a reflective jacket at night?

Yes. Layering a safety vest over a reflective jacket increases visibility. However, ensure the vest's reflective stripes aren't obscured by the jacket. The vest stripes should be over open areas or you can let them extend beyond the jacket. There should be maximum visibility for reflective material from all directions.

Are there safety vests designed for cold weather?

Yes. Insulated vests and quilted vests are available that maintain ANSI compliance while adding warmth. These typically use solid polyester with insulation layers. Look for adjustable side straps (4-6 inches) to fit over heavy winter coats. Some have removable linings for seasonal flexibility. FR-rated insulated vests are available for extreme cold in high-risk environments.